Présentation ACEA

LE MOT DE THIERRY MOHR

directeur général d’ACEA

2018 aura été une nouvelle étape dans la progression et la croissance d’ACEA.

Nous avons constitué à mettre en œuvre la transformation notamment caractérisée par :

– Un changement de notre organisation :

LEAN management, recrutement de nouvelles compétences…

– Les nouvelles technologies : automatisation de process, usine du futur

– La volonté de continuer à progresser dans la satisfaction du client

La transformation et la croissance sont devenues une nécessité du fait de l’évoltuion des marchés des attentes de nos clients et de nos clients et de nos équipes. Dans cette réalité d’un monde en profonde mutation, je place notre responsabilité sociale et sociétale au coeur de cette ambition.

J’ai le profond sentiment que nous progressons continuellement et ceci en étroite collaboration avec l’ensemble des parties prenantes.

Bien faire du premier coup

En 2011, Thierry Mohr a repris et crée ACEA

Applications et Constructions Electroniques d’Alsace

Le site de production implanté à Gundershoffen puisse ses origines

au sein de la société Alcatel : un savoir faire de plus de 30 ans

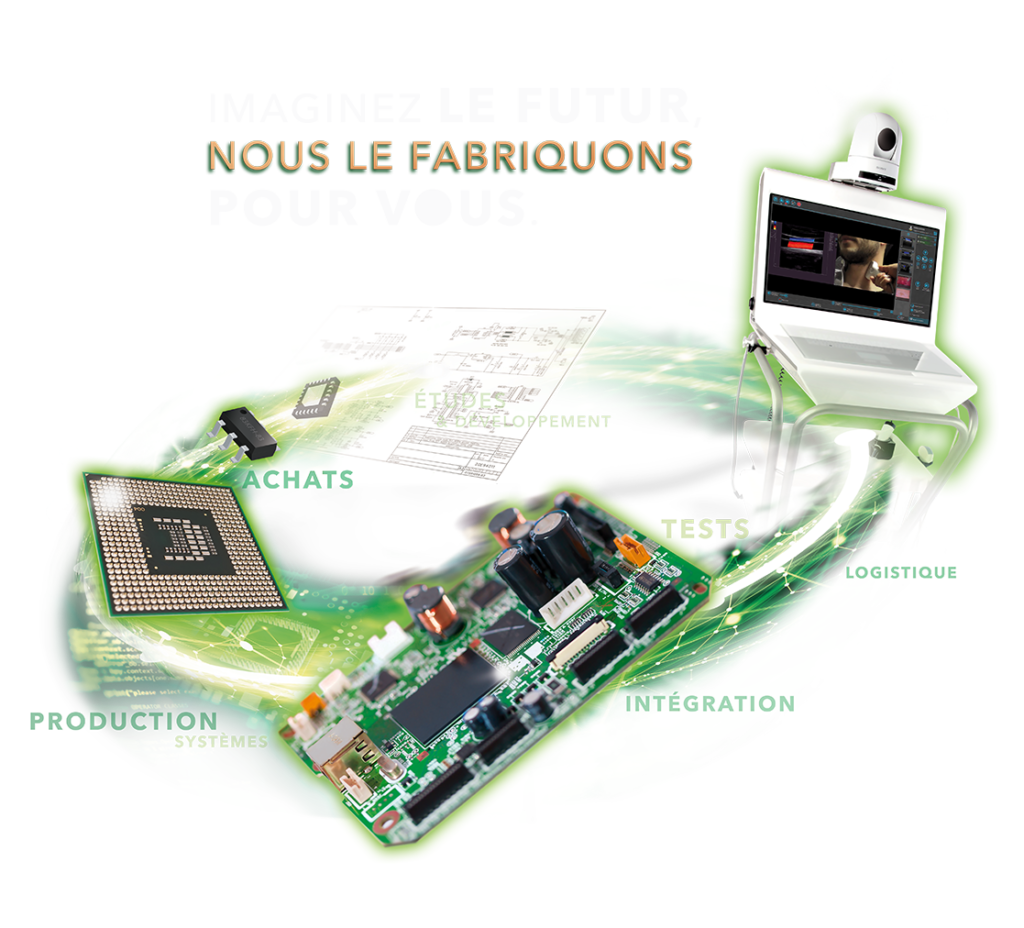

DU POINT DE DÉPART JUSQU’À L’ARRIVÉE.

Générer la satisfaction par des solutions adaptées, fiables et performantes.

Au coeur de l’Europe, ACEA est votre partenaire pour l’industrialisation,

l’équipement de cartes électroniques et le montage d’ensembles et sous-ensembles.

Structure industrielle souple à taille humaine. ACEA vous offre sa capacité d’adaptation et ses compétences liées aux nouvelles technologies. Ses savoir-faire optimisés par un personnel qualifié dans un système « qualité » éprouvé s’organise autour de lignes de production spécialisées

Thierry Mohr, directeur général a repris et créé en 2011 ACEA, Applications et constructions électroniques d’Alsace. Le site de production implanté à Gundershoffen puise ses origines au sein de la société Alcatel, un savoir-faire de plus de 30 ans. Acea réalise un chiffre d’affaires de 10 millions d’euros avec 68 collaborateurs sur le site de production de Gundershoffen de l’ordre de 3000m²

Les valeurs qui accompagnent ACEA :

> La satisfaction du client

> La bienveillance : respect de l’autre, confiance, positivisme, écoute, solidarité.

> Être un acteur responsable : agilité, rigueur, intelligence, pragmatisme, performance

ACEA labelisée industrie du futur

Pourquoi ACEA est une entreprise 4.0 ?

ACEA ET L’INDUSTRIE DU FUTUR 4.0

La transformation de notre outil de production, notre système d’information et de communication ainsi que notre organisation industrielle représentent nos ambitieux projets dans le cadre de l’évolution d’ACEA vers l’industrie du futur4.0

Déploiement du digital dans les ateliers

La numérisation des postes de production est également à l’ordre du jour. L’idée est de remplacer les fiches actuelles d’instructions en papier par des tablettes numériques pour guider les opérateurs dans les tâches à accomplir par des vidéos. L’objectif de cet investissement est double : une meilleure efficacité et une image d’entreprise plus moderne

Automatisation

L’automatisation est une des priorités dans l’évolution et la transformation de l’entreprise. Elle s’illustre d’ores et déjà dans la pose de composants CMS (composants montés en surface) avec deux lignes de pose automatique à haute cadence ainsi que l’inspection optique automatique des cartes électroniques (AOI)? L’objectif est de l’étendre au macimum aux tâches manuelles. Une étude est actuellement en cours avec des élèves de l’INSA et de l’ECPM de Strasbourg concernant la robotisation de la partie résinage de l’atelier.

Projet LEAN PHOENIX 4.0

Enfin, ACEA n’oublie pas l’organisation industrielle avec son projet PHOENIX 4..0 utilisant le « LEAN » comme instrument d’amélioration continue, avec deux maîtres mots : la responsabilisation des opérateurs et la généralisation du management visuel dans l’usine.

Nouveau système ERP

Le système d’information est en cours de refonte pour interconnecter les différents services de l’entreprise, fluidifier l’échange de données et améliorer la gestion de la production. L’ancien ERP vient récemment d’être remplacé par un nouvel ERP. Les objectifs sont multiples : apporter encore d’avantage de flexibilité, réactivité, et bien sûr de réaliser des gains de productivité.

NOTRE ÉQUIPE À VOTRE ÉCOUTE

Thierry Mohr

Directeur général

Fabienne Salpetrier

Ressources Humaines

Michel Walter

Responsable QHSE

Vincent Sabé

Vincent Sabé

Chargé d’affaires

Jean-Luc Latriche

Responsable achats

Aurélien Petit

Chargé d’affaires électroniques

« Notre entreprise peut vous aider dans l’élaboration de votre projet.«

Contactez nous

03 88 09 86 00

5 rue des Genêts, 67110 Gundershoffen

Lundi-Jeudi: 8h00 – 16h30

Vendredi: 8h00 – 12h00

Pour commencer

Nous vous accompagnons du début jusqu’à la fin de votre projets.

NOS CERTIFICATIONS QUALITÉ